Type of work

Tunnels

Aguas Santas Tunnel

Portugal

367 m

new gallery

Construction of the new tunnel in Aguas Santas, in the Aguas Santas / Ermesinde sub-section of the A4 - Porto / Amarante highway

Construction of the new tunnel in Aguas Santas, in the Aguas Santas / Ermesinde sub-section of the A4 - Porto / Amarante highway

Description

The project, located in the municipality of Maia, consists of the construction of a new gallery, with an extension of 367m, to the north of the two existing ones, downwards (Ermesinde / Porto), including the expansion and improvement for 2x4 roads.

The main activities include:

- Excavation (explosives and mechanical means).

- Temporary excavation support (shotcrete with metallic fibers.

- Swellex nailing, metal crankshafts, micro-pile tapping, fiberglass nailing).

- Waterproofing and drainage (2mm PVC geotextile and membrane).

- Ultimate reinforced liner.

- Electromechanical installations (lighting, ventilation, fire extinguishing system, CCTV).

Responsible

Being a work of great social impact, all the principles of good construction rules and greater care in monitoring existing buildings in the surroundings.

Related projects

Type of work

Tunnels

Atocha-Chamartín High speed line tunnel

Spain

6,82 km

longitud

Description

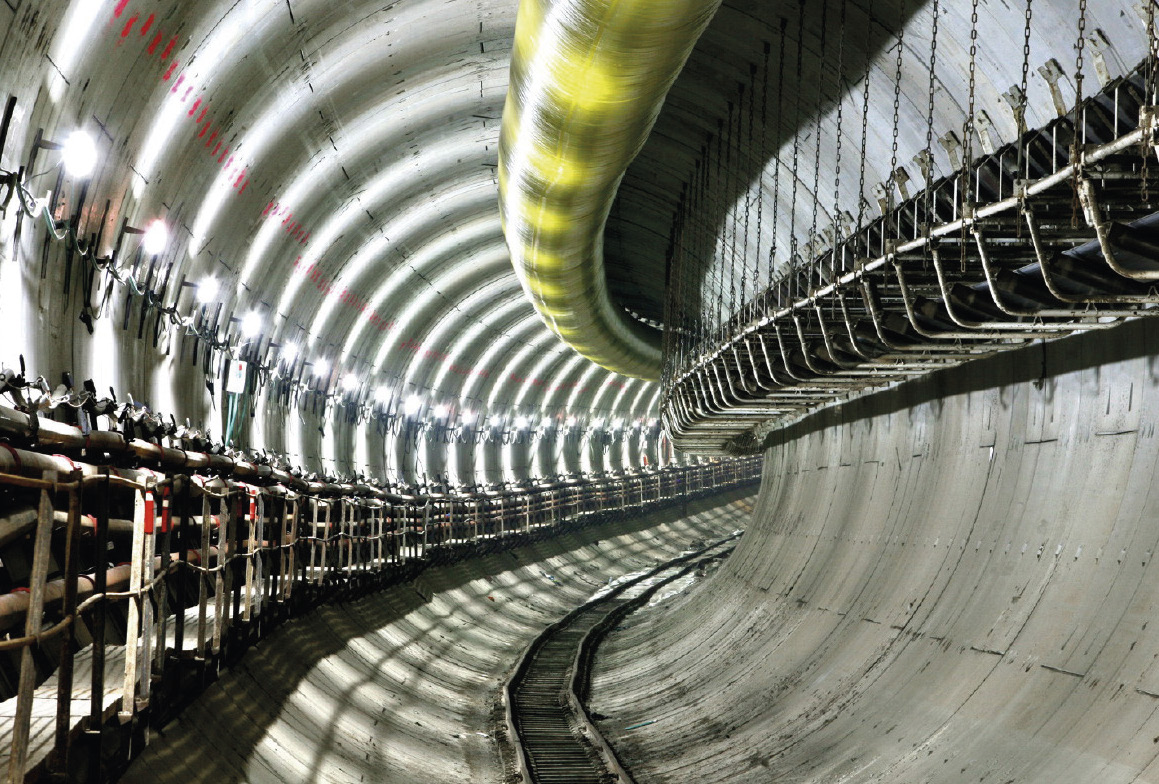

The works consist of the execution of the platform and a railway tunnel to connect the Atocha and Chamartín stations, both of which are in Madrid and for exclusive High-Speed AVE train transit.

The tunnel allows the coordination of the railway connection with destination or origin in the southern and eastern half of Spain with the lines in the north.

Bored to accommodate double international track and width, the tunnel length is 6.82 kilometers.

Most of the tunnel was excavated with a tunnel boring machine (TBM), except one 110 meters section near Chamartín Station, which was executed on the surface. The tunnel was lined with 1.8 x 0.36 voussoirs that were assembled by the TBM and it also has eight emergency exits.

It also includes the remodelling of the marshalling yard at the south head of Chamartín Station in order to enable the arrival of the high-speed here through the tunnel that will connect with the future expansion of Puerta de Atocha Station.

This railway connection between Atocha and Chamartín stations forms an essential infrastructure for the development of a vertebral network of international width in Spain.

Highlight

- The tunnel execution was an engineering challenge, given the urban environment in the which it was executed; requiring multiple crossings with existing heritage buildings, and transport infrastructure.

- A tunnel that allows the coordination of the railway connection between the southern and eastern half of Spain and the north.

- It increases safety, with the adoption of cutting-edge technologies in automatic train driving systems.

Related projects

Type of work

Tunnels

Barcelona Metro Line 9

Spain

4,29 km

longitud

Section 4 Bon Pastor - Can Zam.

Section 4 Bon Pastor - Can Zam.

Description

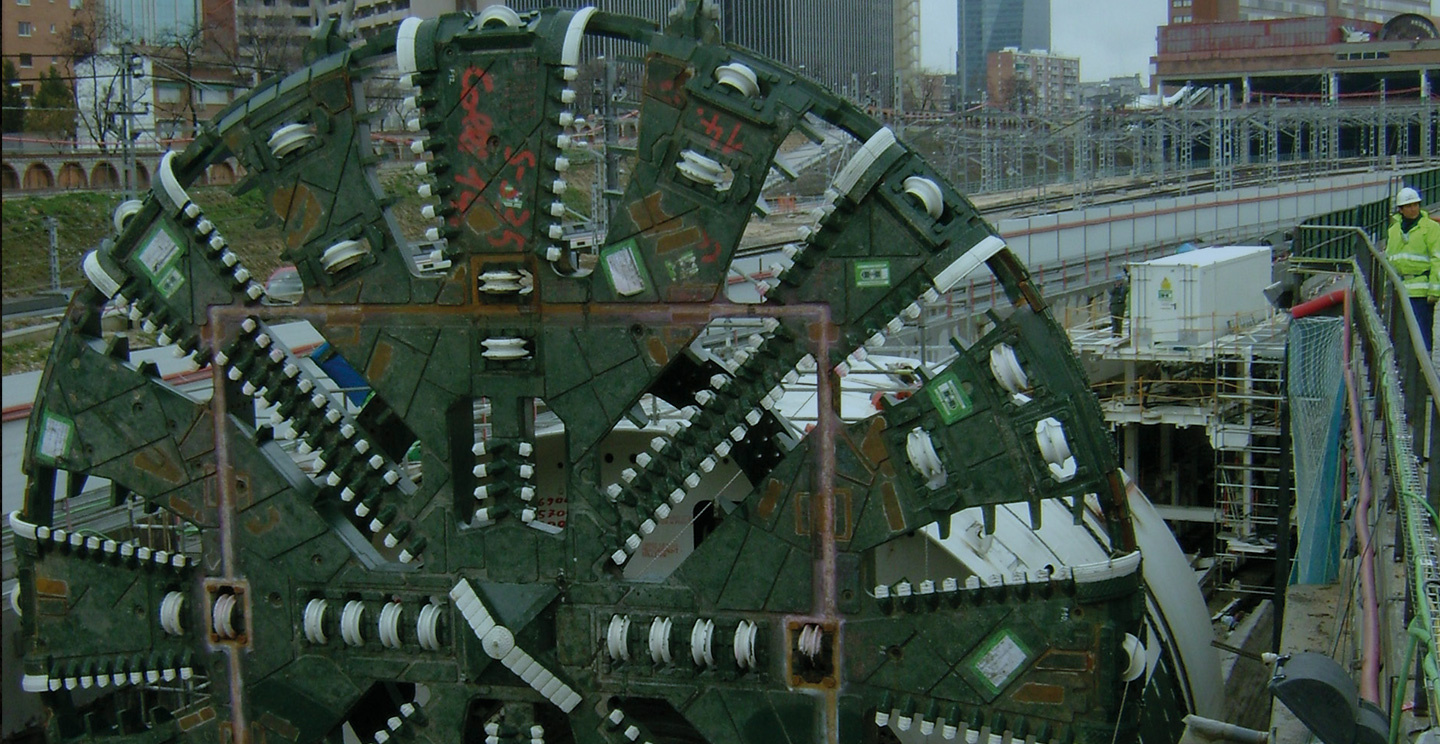

The line connects the neighbourhood of Bon Pastor with Oliveres. Section 4 of line 9 of the Barcelona metro, was 4.29 kilometers, and was executed by tunnel boring machine. Construction was carried out with a TBM capable of working in open mode and closed (EPB).

Related projects

Type of work

Tunnels

Barcelona Metro Line 9. Southern section

Spain

19,5 km

longitud

13

estaciones

Description

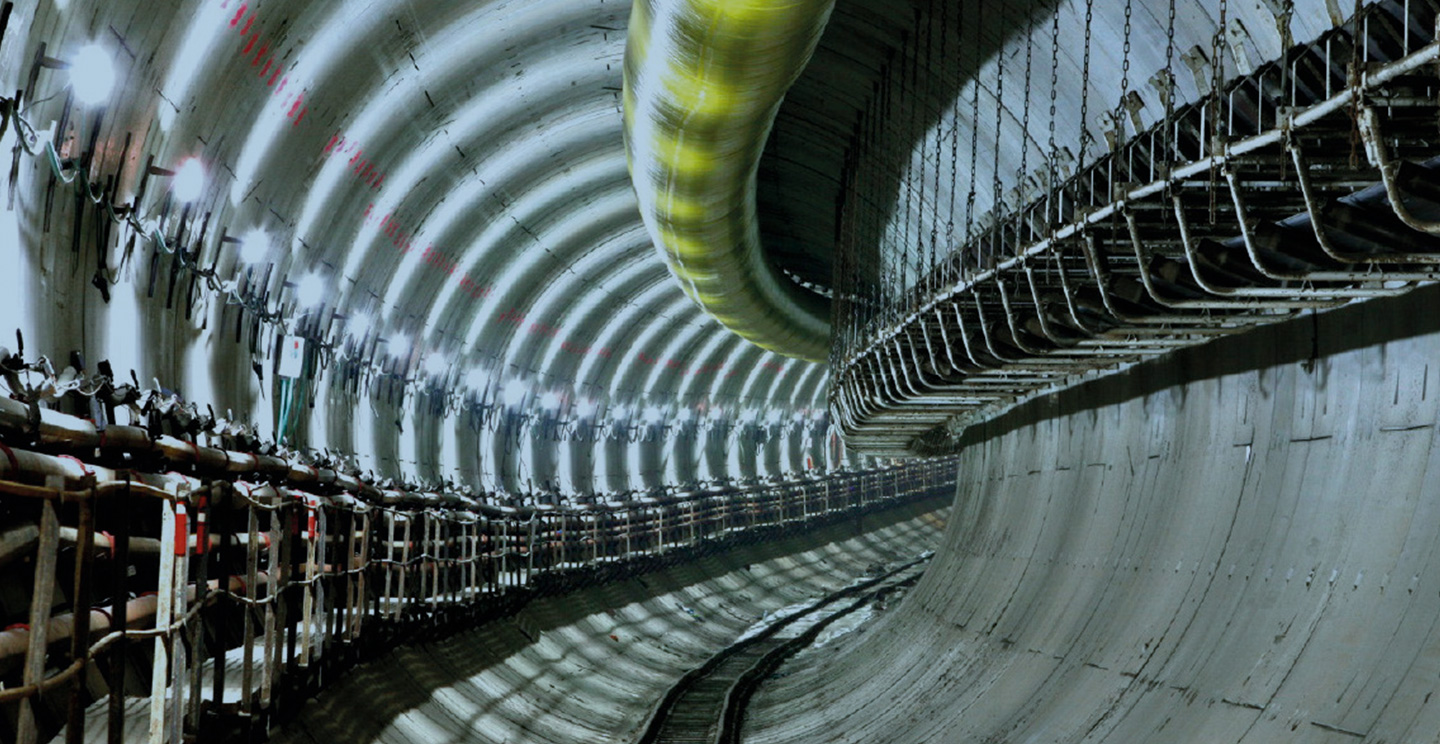

The extension of the southern section of line 9 joins the University Zone station, in the district of Les Corts, with the T-1 and T-2 terminals of the Prat airport. FCC built 14.9 kilometers of tunnels to cover; 7 stations and 13 ventilation wells, with a total of 19.5 kilometers underground and 13 stations in the

entire section

In 2017, the section of Metro Line 9 was awarded Section University Zone-T1 Barcelona Airport.

Related projects

Type of work

Tunnels

Bracons Tunnel

Spain

4,57 km

longitud

Description

The Bracons tunnel is located on the Torrello - La Vall section d’en Bas of the new Vic - Olot road (Barcelona). Has a total length of 4.57 kilometers. The construction method employed was the New Austrian Method (NATM), digging the tunnel to full section and using seven types of support.

Highlights

The construction of this infrastructure was of paramount importance for the Vic - Olot road, reducing the time taken to travel between the two communities by half.