Type of work

Industrial

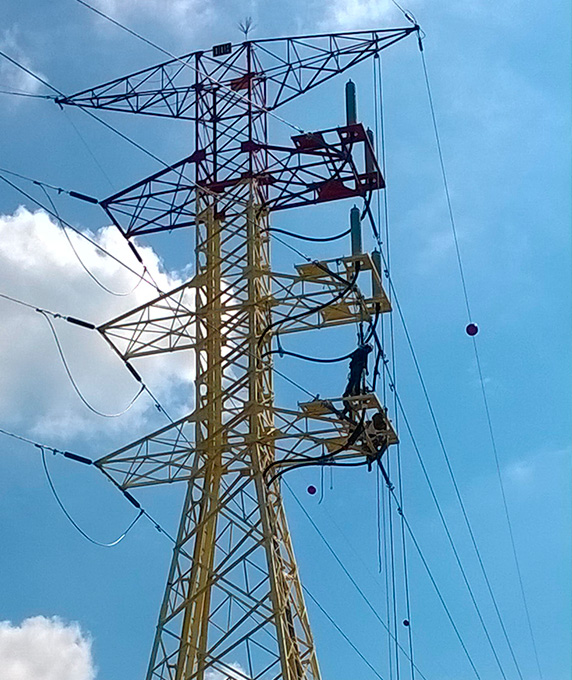

Campeche electrical substation

Mexico

Description

Project 288 SLT 1722 DISTRIBUCION SUR (1 PHASE), consists of a “turnkey” (EPC) that consists of: GIS substation of 115 / 34.5, 13.8 kV, five bays and a capacity of 80 MVA and 4.8 MVAr of compensation, 16 Metalclad high voltage / medium voltage LAAT 115 kV cells and medium voltage distribution lines including the dismantling of the existing substation.

The work was carried out by modifying and replacing the existing electrical substation without loss of service at any time.

Responsible

This work will benefit more than 500.000 homes, enabling an improvement in energy efficiency.

Related projects

Type of work

Industrial

Duplication of the Gasoducto Tivissa - Paterna

Spain

53.378 m

total length

Center section: pos 15.12.d – pos. 15.18.d

Center section: pos 15.12.d – pos. 15.18.d

Description

The gas pipeline starts from Position 15.12.D, located at T.M. from Vilanova d´Alcolea, province of Castellón and ends its route at Position 15.18.D, located at T.M. from Villarreal, province of Castellón.

It is a large diameter pipeline with steep slopes and intersections with affected services.

The work consists of the construction of the Duplication of the Tivissa-Paterna Central Section Gas Pipeline whose main characteristics are listed below:

- The total length is 53,378 meters.

- The pipeline to be installed is 40 ”in diameter, it will be made of API 5L Gr.X-70 quality steel and a maximum thickness of 22.2 mm, whose weight per linear meter is 544 kg / ml

Related projects

Type of work

Industrial

Enagás Tanks

Spain

In order to tackle the increasing demand for natural gas being experienced in the Barcelona Metropolitan area, Enagás decided to construct four storage tanks on the inflammables quay in the Port of Barcelona.

The project, carried out by FCC, consists of the EPC construction of storage tanks LNG TK-3000, TK-3001, TK-3002 and TK-3003 and their auxiliary installations at the Enagás regasification plant.

The cryogenic tanks are constructed using pre-stressed concrete and each has a capacity of 150,000 cubic metres, with an inside diameter of 80.20 metres and a height of 39.60 metres, crowned by a dome that is 10 metres high at the centre.

The natural gas is kept in a liquid state at temperatures below -162ºC, for which reason, containment techniques were employed and the inside of the tank is lined with cryogenic steel with 9% nickel. The whole assembly is insulated by using foam-glass and perlite.

These storage tanks for natural gas in a liquid state are an example of FCC's industrial activity in this field, providing a comprehensive hydrocarbon transport and storage service.

Premio Fomento de la Calidad a la Obra Excelente 2011

Related projects

Type of work

Industrial

Guzmán thermosolar

Spain

340,000 m²

surface area

384

collectors

Description

The Guzmán plant is located in Palma del Río (Córdoba, Spain) and is a thermosolar installation for electricity generation based on heliostats that concentrate sunlight. The plant is fitted with a solar farm with cylindrical, parabolic reflectors (heliostats) that concentrate sunlight to produce thermal energy that is then employed to generate electricity by means of a steam-generator turbine unit having a total net power of 49.9 MW. The plant employs cylindrical, parabolic technology for the 96 loops that form the solar farm. Each loop consists of four sections of collectors of approximately 150 metres length and connected in series distributed in two parallel rows, producing a total of 384 heliostats.

The Palma del Río installation is the first joint project in the power field between FCC Group and the Japanese multinational Mitsui & Co. Ltd for the development of thermosolar energy in Spain.

The Palma del Río plant covers a zone that is larger than 200 football pitches and has an area exceeding 340,000 square metres of parabolic mirrors that automatically imitate sunflower movement during daylight hours, steering themselves from dawn to dusk in order to reflect the maximum amount of sunlight and aim it towards a collector tube full of oil that attains a temperature of more than 400 degrees centigrade.

The new plant benefits from the privileged location of the Municipality of Palma del Río, which is among the European locations with highest levels of sunlight, in addition to having easy access to water, auxiliary gas supplies and adequate electricity evacuation structures.

Responsible

The thermosolar plant is located in Palma del Río, one of European locations with the highest levels of sunlight.

With an annual production of 198.5 million kW, the power station produces sufficient electricity to satisfy the needs of 30,000 homes and reduces CO2 emissions by approximately 108,500 tonnes a year.

Guzmán Energía is the company that owns the plant in Córdoba, with its shareholders being FCC Energía with 70% and Mitsui Renewable Energy Europe with 30%.

Related projects

Type of work

Industrial

Integration of the Montrepós Tunnel Control System

Spain

Integration of the Control Systems of the highway tunnels of the Demarcation of Huesca

Integration of the Control Systems of the highway tunnels of the Demarcation of Huesca

Description

Comprehensive project for ITS installations on the highway and control of highway tunnels and the Monrepós Control Center.

Includes subsystems:

- Control center

- Traffic Management Software

- Communications Network

- Variable Message Panels

- Closed Circuit Television

- Weather Stations

- ERU and ETD stations

- SOS IP poles

- Lighting control

- Ventilation control

Energy Monitoring

Integration in the Monrepós Control Center of the Petralba, Berroy, Nueno tunnels and the T-4, T-5, T-6 tunnels.